New Schaller S-Locks

In 2018, Schaller will pave the way for the next generation of revolutionary strap locks.

In 1981, Schaller developed and got the patent for a totally new category of product, which revolutionized the connection between guitar and strap.

With its unique design and functionality, Schaller has been setting the standard in strap locks for decades.

We protect your beloved instruments.

The new S-Locks.

S for safe, S for silent and S for Schaller strap locks!

These new revolutionary S-Locks are silent. They feature one-piece hardened steel strap buttons, aesthetic design, perfect handling, an elegant Lock-Wheel and all former hiccups have been tackled!

New silent feature for noiseless performance while moving and playing your instruments.

choose from 8 different colours

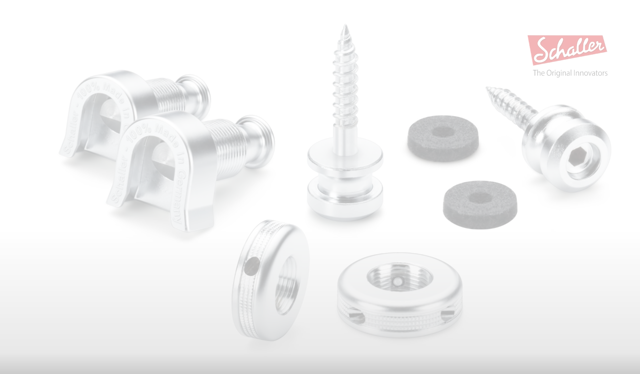

3 pieces = 1 S-Lock - perfect

Strap button

New and unique solid one-piece strap button in hardened steel with self-tapping wood thread. Simply screw it on with an Allen key (size 3 mm/ 1/8").

4 mm/ 5/32“ screw with self-tapping wood thread. Fits almost all existing standard strap buttons incl. nearly all Gibson for perfect replacement without adjustments on existing holes and screws (XL and S version also available as replacement kit).

Hardened steel and more than double thickness of the strap button guarantees maximum security against breakage.

Including high-grade felt washers for ultimate protection of guitar's finish.

Lock

Extended thread length for holding straps of up to 6 mm thickness.

New designed slanted locking bolt in stainless steel for permanent precision, reliable performance and wear-free finish.

New designed pull-up ball for easy-grip lock and release.

Lock-Wheel

New Lock-Wheel with unique 3-Step security function

You will never lose your wheel again!

Finally put all parts together and just listen carefully

Give it a shake, give it a roll and prepare to be amazed:

It is silent!

New silent feature for noiseless performance while moving and playing your instruments.

Schaller - the Original Innovators!

All S-Locks come in a new and attractive re-usable crystal box.

Two more things ...

- strap button old SecLock + lock new S-Lock

- strap button new S-Lock + lock old SecLock only limited, we do not recommend it.

Bitte an Ihrem Gurt immer unser neues S-Lock Schloß mit Lock-Wheel verwenden, dann sind Sie immer zu allen Gurtpins kompatibel und nutzen gleichzeitig immer alle Vorteile unseres neuen Lock-Wheels.

2. You need only one strap and one pair of S-Locks for all your guitars!